I had long wanted to build a big bore, high HP Corvair motor. I had read all the books and done lots of internet forums and was convinced I knew the recipe on how to do this. About a year after I bought the GS, I bought a large stash of vintage Corvair speed parts. An original GS owner was found on the web. His GS was long gone, but he had saved the best parts. The key parts were the Weber IDA3C carburetors, Crown manifolds and modified 140 heads. These were the parts that would really wake up the Corvair. The Corvair is severely limited in the intake department. The Crown conversion adapts the Carburetors from the 2.7 Liter Porsche 911 to the Corvair 140 cylinder heads. The 140 head has larger valves than a standard Corvair and intake with pads for 4 one barrel carburetors, rather than two. With this conversion, the stock intake pad is milled away and the Crown manifolds bolts on. This requires extensive machine work to modify the heads. Mine had already been modified, but the Heads needed to be redone as water had gotten into the engine and the valves and seats were a mess. My thought was that If I had to do head work, this was the set to do it to.

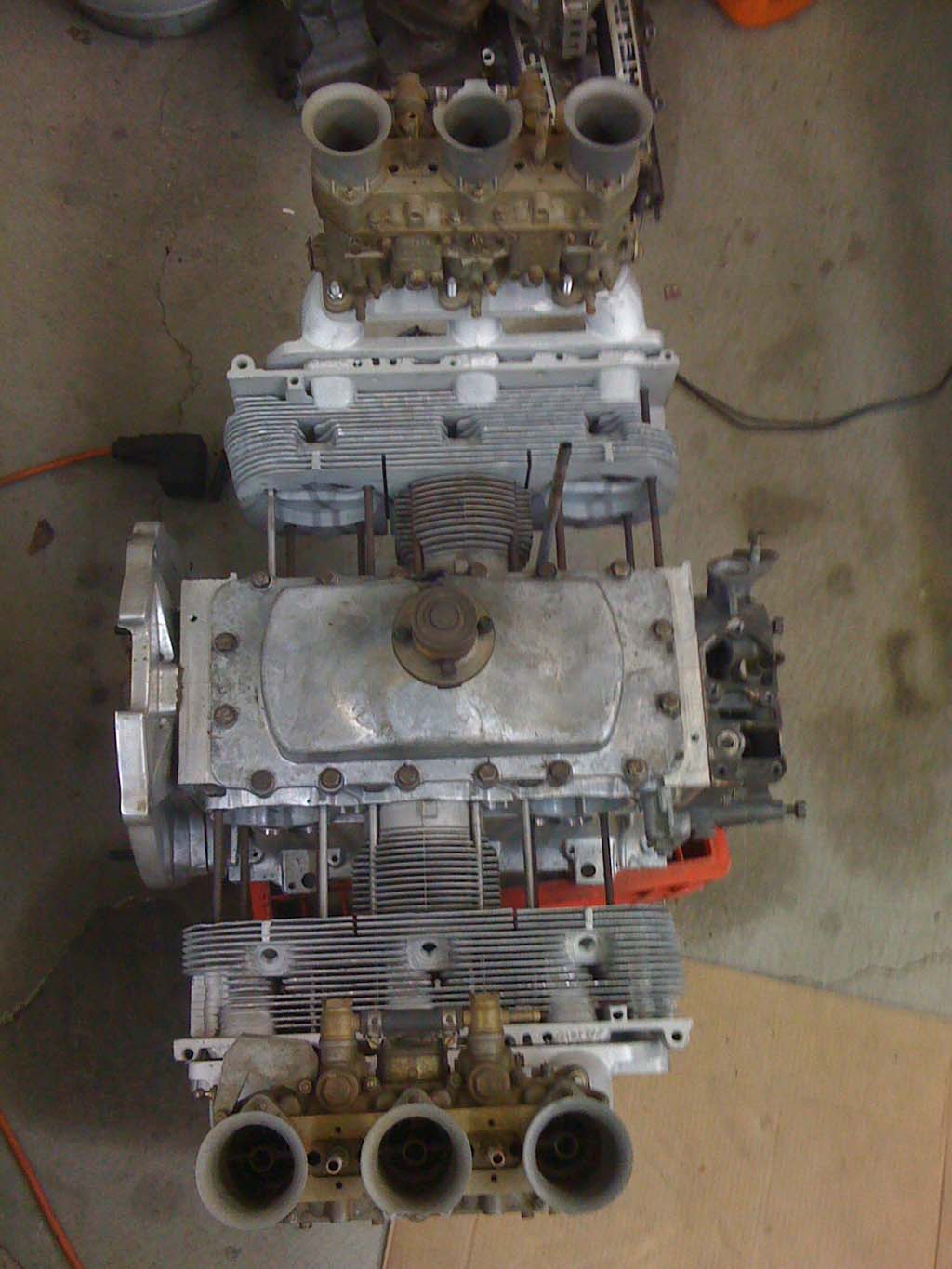

Corvair 140 head with crown manifold.

New valve seats needed.

Weber IDA-3C carbs, stock on Porsche 911 and some Lamborghinis.

All the parts loot.

I put these parts away for a rainy day. The 102 hp that came in the GS was a strong runner. I wanted to log miles on the car. Unfortunately the 102 hp seized during my third AutoX event, just when I was starting to understand the car. The next motor I installed was a stock low mileage 95 hp. This was resealed and installed along with some updates with reliability in mind. Unfortunately, the high ethanol in the gas dissolved the diaphragm in my fuel pump and filled my crankcase with fuel. The poor bearings didn't have a chance...

I was able to take the crank, .060 over TRW forded pistons, rods, flywheel, pressure plate from the other GS owner plus the balancer from my 95hp and have them balanced at ABT machine. Bottom end was looking good. I ordered cylinders from Clarks. Next up would be bearings.

About this time, I was able to find a complete 1965 Corvair 140 in Western Massachusetts. After a two hour drive I was able to pickup this engine for the paltry sum of $5! It was seized, but very valuable in parts alone.

I removed the individual Rochester H carbs and bolted up my IECO 140x1 intake that I got in the parts loot. I wanted to see how it would look.

Some use of the pressure washer got the engine looking better.

I had one of my little helpers.

Looking better, but no amount of oil in the cylinders would unstick the engine.

So it was time for a tear down!

Most of this was still good. I would end up using the cylinders as cores for .060 cylinders from Clark's.

More pressure washing to clean the case.

Ready to remove the seized 95hp from the GS.

Getting too used to this.

This will donate some parts to the new motor.

I was able to clean the heads up with my Beadblasting cabinet and also spend some time deflashing the cooling fins. I then mocked up the engine so I could test fit. The Webers would extend into the engine cover which I would need to modify. I had a second copy of my original thanks to Bob Elliott. He used my original as a mold.

Mock up engine in the GS. You can see the machine work that was done to the heads.

Ultimately, I put this eninge project on hold. Along with the valve seats I was going for the slant port exhaust to open up the exhaust to match the intake. This would require new headers too. The head work was going to easily exceed $1000. It was then that I was presented a NOS rebuilt 140 in trade. This was a drop in and go, or so I thought....